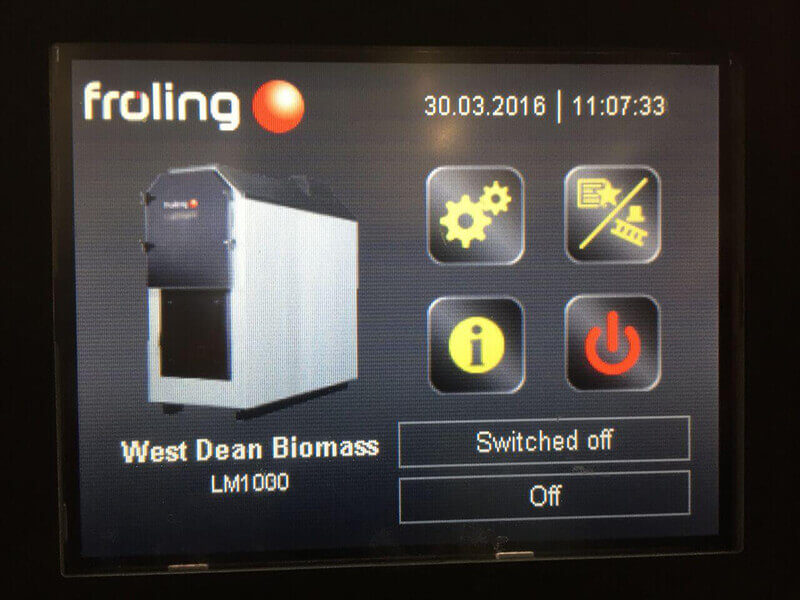

Fröling LM KOM-H 1000, Woodchip Heating System

Set in 6,400 acres of countryside, West Dean Estate comprises of West Dean Gardens, College and Tapestry Studios. This large complex of 65 buildings includes 6,500sq ft of new teaching and exhibition space and accommodation for residential students and holidaymakers.

The original biomass district heating system was commissioned in 1981, with other additions in later years. Over time the boilers became unreliable and inefficient, prompting West Dean to upgrade to a much more advanced system provided by Dunster.

Dunster installed the biomass boiler, fuel feed system and ancillary equipment for Lorne Stewart PLC, who were the principal contractor on the project.

Fuel Supply and Chip Handling

Fuel is provided from the 2,000 acres of woodland on the site.

The Fröling LM 1000 was chosen for its extreme versatility when it comes to fuel. This system is designed to take G100 woodchip with moisture content up to 50%. This is possible by having the hydraulic ram stoker in combination with the hydraulic cross feeder. The chip is loaded onto the walking floor with the telehandler, from here the hydraulic system takes over to feed the boiler at the required rate of demand.

System Design and Installation

The design of the boiler and fuel store layout was completed by Dunster’s in house CAD team but was overseen by the project’s consultants SEL.

Benefits

Dunster’s effective boiler installation and ancillary connection has improved the heat network at West Dean Estate and reduced disruptions and costs.

April 2016

To provide heating and hot water to West Dean Estate.

A Fröling LM KOM-H 1000 commercial boiler was installed, working in conjunction with two 740 kW oil boilers in a new bespoke plant room. The Fröling LM replaced an existing failed old 1.2MW biomass boiler.

The boiler is expected to use around 400 tonnes of woodchip per annum and up to 30 tonnes per week in the coldest weather.

The fuel store has been constructed from reinforced concrete panels with the 4m x 6m Fröling walking floor system installed. Loading is completed with the sites loader.

The system was funded by West Dean Estate and is accredited under the Non-Domestic Renewable Heat Incentive scheme.

The new Fröling biomass system is reliable, durable and energy-efficient. It is a massive upgrade from the previous biomass system and will save the estate significant time and money.

The estate previously had a Biomass system so savings on this are low but the site should see an increase due to the boiler efficiency.

Our 90kw ETA Hack wood chip boiler suffered water damage in late 2014. Dunster Biomass Heating was the only company that could fix the issues without costing me new components. What we have learned is simple. Experience is key! When there is an unusual problem you need more than a guy with a manual – you need a company with the expertise, ability and willingness to solve the problem!