ETA Hack 220Kw & 93kW Wood Pellet Heating System

Saltram House is a magnificent National Trust stately home in Plymouth. The building boasts many fine examples of architectural design and is regarded as one of Britain’s finest Georgian houses.

As part of the National Trust’s Renewable Energy Investment Programme, the aim of this project was to significantly reduce environmental impacts through lowering carbon emissions, environmental damage and risks associated with potential oil spills. Dunster replaced the existing oil system with a pellet biomass system.

Fuel Supply and Pellet Handling

A tailor-made fuel store was built ensuring dust, moisture control and effective ventilation. The store is easily accessible and designed to take deliveries of up to 45m3 via a tipping trailer, minimising the need for any onsite handling of pellets.

It is anticipated that the client will purchase pellets from a local supplier.

System Design and Installation

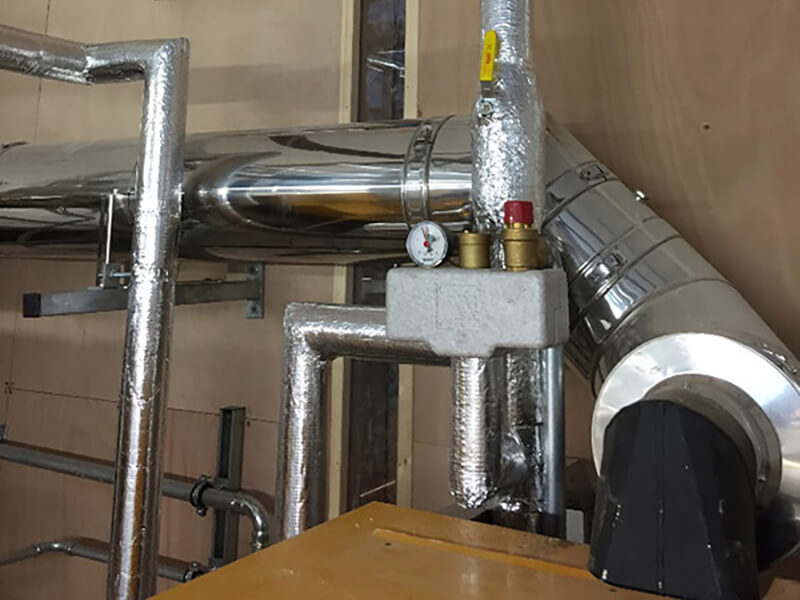

The system was designed for 100% of heat and hot water to be provided by Biomass. Installation consisted of the two pellet biomass boilers, three thermal stores to meet the requirements of the system, fuel feed systems, flue system, all mechanical services and electrical works associated with the install. Dunster also constructed the fuel store and fuel filling system. The installation was a success despite space constraints and other challenges that come with installing a system within a historic landscape.

Benefits

Dunster’s effective planning ensured minimum impact on the historic fabric of the site and its gardens. With biomass heating, Saltram house has significantly lowered its carbon emissions and energy usage while increasing its environmental credentials.

December 2015

Supply of heating and hot water to Saltram House and surrounding

National Trust buildings.

ETA Hack 210 and ETA Hack 93kW pellet boilers with a combined maximum output of 313 kW and three Galu thermal stores, installed in the laundry building.

The boilers use 101 tonnes of wood pellet per annum, producing around … of heat. By switching from oil to wood pellets, the property will save around £20,885 per annum.

Dunster constructed a bespoke, tailored fuel store, with viewing panels and moisture minimising technology. The fuel store has a total volume of 25 tonnes and pellets are delivered via bespoke pipe extensions to the connections points in the fuel store.

The system was funded by the National Trust and is accredited under the Non-Domestic Renewable Heat Incentive scheme.

An attractive return on investment, in excess of 18%, plus short payback period of 5.4 years.

Compared to oil heating, our wood pellet system reduces CO2 emissions by over 95%.

Our 90kw ETA Hack wood chip boiler suffered water damage in late 2014. Dunster Biomass Heating was the only company that could fix the issues without costing me new components. What we have learned is simple. Experience is key! When there is an unusual problem you need more than a guy with a manual – you need a company with the expertise, ability and willingness to solve the problem!