ETA HACK 500kW Wood Pellet Heating System

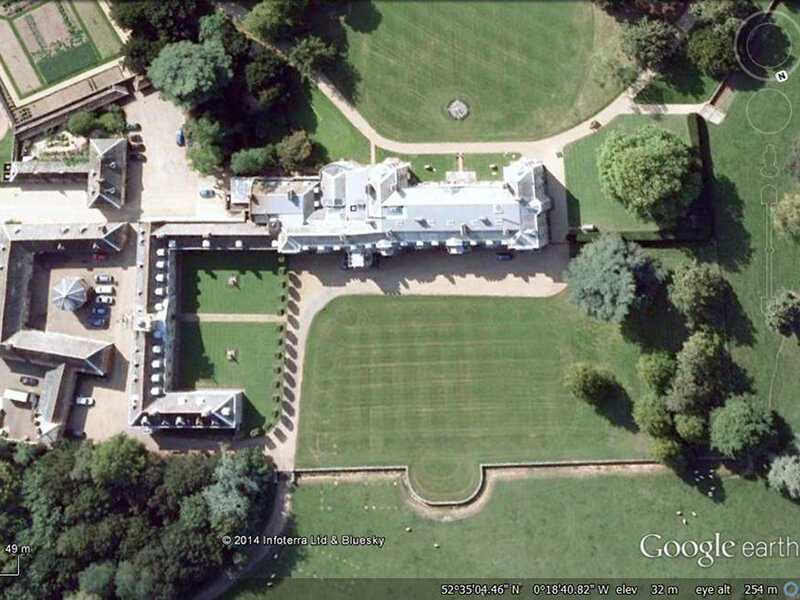

This property is one of the top ten largest residential houses in the UK, boasting the 17th-century architecture and 35 acres of beautiful gardens.

The estate was looking to reduce its reliance on fossil fuels and opt for an affordable and reliable green heating system. Dunster was invited to assess heat usage and recommend the most efficient, environmentally friendly system.

Fuel Supply and Pellet Handling

A tailor-made fuel store was built ensuring dust and moisture control and effective ventilation. The store is easily accessible and designed to take deliveries of up to 45m3 via tipping trailer minimising the need for any onsite handling of pellets.

It is anticipated that the client will purchase pellet from a local supplier. This is brought by tankers and blown into the store. Pellet handling?

System Design and Installation

The system was designed for 100% of heat and hot water to the hall and surrounding stables. Heat would be transferred by hot water through insulated pipes from the biomass plant room to the Hall and a separate twin-pipe from the plant room to the stables block.

All pumps and controls were upgraded to modernise the heating system and increase efficiency across the heat network. The entire site was fully networked ensuring that all boilers and controls can be managed from one office computer.

Access was maintained by careful planning and installing the main sections of heat main during a quiet period, followed by phased installation of the separate buildings.

Benefits

Dunster was able to successfully provide state-of-the-art heating to the estate without impacting on the historic fabric of the site and its gardens. The estate now enjoys green heat, along with increased savings.

March 2015

Supply of heating and hot water to Northamptonshire Hall and stable buildings.

ETA HACK 500 boiler with a rated output of 499kW, linked to a 10,000 litre Galu thermal store housed in a bespoke biomass plant. Their previous oil boiler is being used as a back- up.

The boilers use 187 tonnes of wood pellet per annum, successfully meeting the annual heat demand of 763,587kWh. By switching to wood pellets, the estate is saving around 43,846 per annum.

Dunster constructed a tailored fuel store, with viewing panels and moisture minimising technology. The fuel store has a total volume of 25 tonnes.

The system was privately funded, and is accredited under the non-domestic Renewable Heat Incentive scheme.

An attractive return on investment, in excess of 15%, plus short payback period of 6.5 years.

Compared to oil heating, our wood pellet system reduces CO2 emissions by over 95%.

Our 90kw ETA Hack wood chip boiler suffered water damage in late 2014. Dunster Biomass Heating was the only company that could fix the issues without costing me new components. What we have learned is simple. Experience is key! When there is an unusual problem you need more than a guy with a manual – you need a company with the expertise, ability and willingness to solve the problem!