315Kw Wood Pellet Heating System

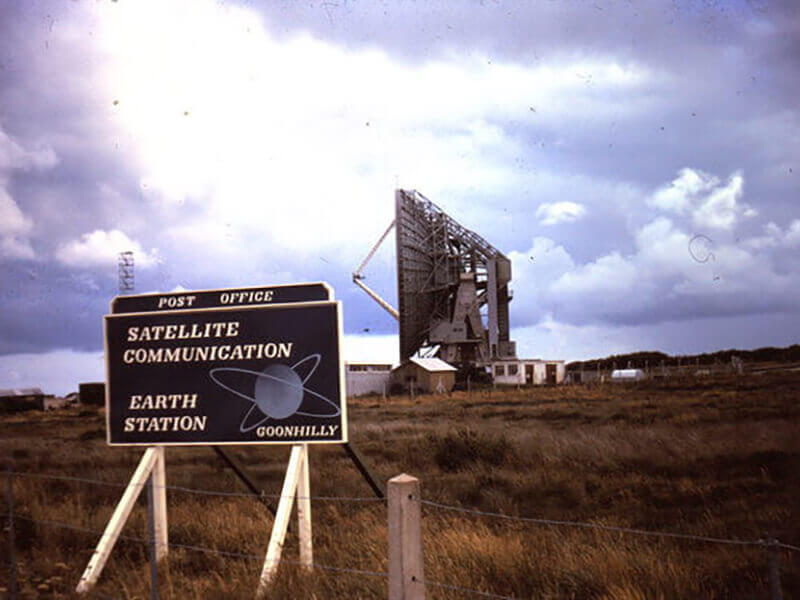

Goonhilly Earth Station in Cornwall is a space science centre, famous for its satellite communication, space educational resources and community engagement activities.

The earth station sought to enhance its green credentials and reduce energy costs by switching from oil to biomass heating for their main building. The main building is 3,500 sqm in size, with an annual heat demand of approximately 420,000kWh.

Fuel Supply and Pellet Handling

In order to avoid additional construction costs and disruption, Dunster built a unique, containerised pellet store off-site, which was then easily installed. The steel store has been completely insulated and then finished internally with phenolic ply, helping to ensure the free flow of pellet. Being long and narrow we installed three pellet injection connections to ensure that maximum capacity can be used. Wood pellet is being purchased from a local supplier.

System Design and Installation

As mentioned, Dunster designed the biomass system and fuel store to fit within new ISO containers; this was built to match the original construction, with an added twist of colour to brighten up the site.

The system was designed to take on 100% of the heat load for the main building. Three P4 105kW boilers were installed in cascade with a 6,500Ltr accumulator tank, providing excellent modulation and built-in backup.

The Fröling control system has been connected to the internet to enable remote monitoring and access, meaning even the most remote locations such as this one are visible at the touch of a button.

Benefits

Compared to their previous oil heating system, the biomass scheme is much more efficient and has provided a cleaner, greener source of heating. Biomass heating at Goonhilly Earth Station has allowed the organisation to reduce energy costs and CO2 emissions.

December 2015

Supply of heating to the main building of the Goonhilly Earth Station.

Fröling 315kW wood pellet biomass system, installed with an existing oil backup system. The plant room and fuel store were built in bespoke energy centres, matching an existing site-building in the same location.

The boilers are expected to use around 101 tonnes of wood pellet per annum, producing around 480,000kWh of heat to the site. The system is designed to run on wood pellets, keeping the storage space to a minimum.

Dunster utilised a brand new 30ft shipping container as a store, and then installed three pellet augers along its length, maximising available space and providing 21 tonnes of storage.

The system was funded by the Goonhilly Earth Station and is accredited under the Non-Domestic Renewable Heat Incentive scheme.

Switching from oil to biomass heating is providing significant savings on heating bills. Additionally, the income from RHI payments will pay off the capital expenditure of the system.

Compared to oil heating, our wood pellet system reduces CO2 emissions by over 95%.

Our 90kw ETA Hack wood chip boiler suffered water damage in late 2014. Dunster Biomass Heating was the only company that could fix the issues without costing me new components. What we have learned is simple. Experience is key! When there is an unusual problem you need more than a guy with a manual – you need a company with the expertise, ability and willingness to solve the problem!